B.U.M.E.S Optimization and Vision Integration

Background

B.U.M.E.S (Boston University Manufacturing Execution Software) is a fully automated system for manufacturing and assembling a cord organizer (also known as a cordganizer), consisting of two distinct parts:

● Lid Piece (1.5” x 3” x 0.25” Polycarbonate)

● Base Piece (1.5” x 3” x 1” HDPE)

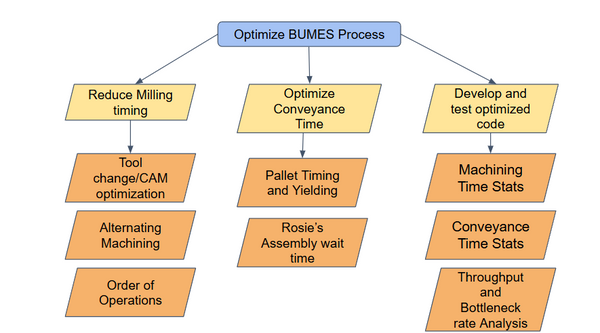

The goal of this project:

-

Optimize BUMES by integrating Lean principles to increase throughput, reduce waste and defects.

-

Utilize vision system as a post-manufacturing process that automatically identifies and sorts machined parts into specified categories.

Success will be measured by reductions in defect rates, waste, and cycle time, leading to a more efficient and scalable manufacturing process.

Technical Details

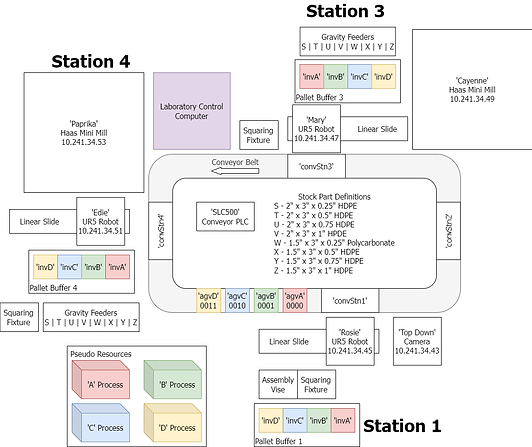

The lab plan view on the right features three UR robots (Rosie, Mary, and Edie), two CNC machines (Cayenne and Paprika), and a conveyor belt, all of which are at the core of the manufacturing process.

Currently, the cycle time for two cordganizers (2 lids and 2 bases) is 25 minutes.

Aim 1: CAD/ CAM Optimization

-

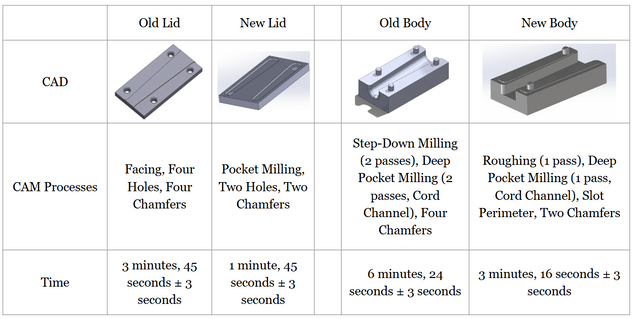

Changes in Lid and Body CAD

-

Changed from 4 to 2 holes/pegs

-

Added a snap fit feature to lock them in place

-

-

Changed in Lid and Body CAM

-

Increased tool feed rate

-

Performed single pass runs

-

Decreased number of tool change

-

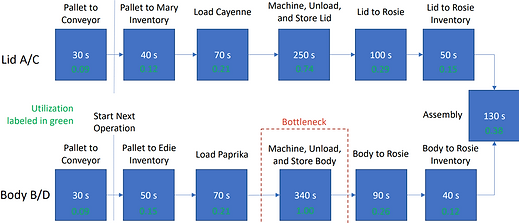

Aim 2: BUMES Process

-

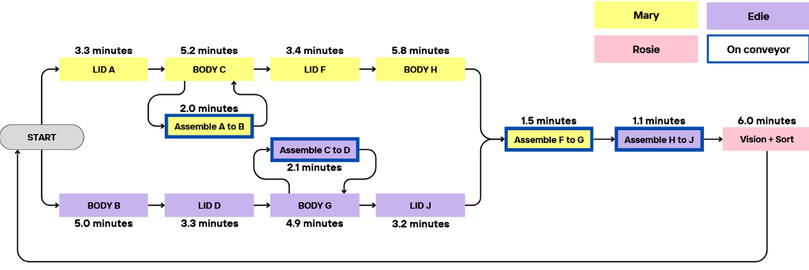

1 BUMES cycle → 4 cordganizers + vision + sorting

-

Total time: 24.6 minutes

-

-

13 individual programs to achieve system optimization

-

Lids and bodies are individually called from A to J (excluding E and I) to minimize confusion in the script

-

Eliminate the third robot (Rosie) by performing assembly on conveyor

-

Alternate machining between the two CNCs

-

Could run infinitely after including Vision in the BUMES process

-

All UR waypoints are optimized to reduce NVAT

-

Before

After

Aim 3: Vision-Based Part Identification and Sorting

-

Added blue tape to some of the lids before production

-

Developed UR scripts to control part handling, positioning, and interaction with the vision system

-

Implemented a vision system to classify and sort Cordganizers based on paint color using camera feedback

-

One of the first groups, that were able to integrate the vision system with the BUMES process

Documentation

BUMES Operation Guide and Supporting Documentation

CAD/CAM Supporting Documentation

Vision Python Scripts Supporting Documentation

Universal Robotics Arms Supporting Documentation

Outcomes/lesson learned

-

Developed an optimized version of the BUMES process by reducing cycle time and increasing throughput.

-

Created new “.urp” files, enabling robots to machine tend, place parts on pallets, and assemble Cordganizers.

-

Reduced milling time by optimizing tool changes in CAD, alternating machining, and using optimal spindle speeds for improved part quality.

-

Identified bottlenecks and NVAT operations, optimized CAM files, and streamlined assembly for greater efficiency.

-

Successfully automated object sorting on a live manufacturing station, improving task execution reliability and adaptability within the BUMES environment.

-

Established communication with robots to sort Cordganizers into their respective bins after manufacturing.

-

Optimize CAM for exclusively snap fit to reduce milling time and tool change

-

Eliminate burring; add finishing passes or decrease milling feed

-

Implement more vision features (size, holes, details etc)

-

Integrate real-time data logging and process tracking to monitor part flow, system performance, and error rates for continuous improvement.

-

Modify the gravity feeders to improve consistency and ensure repeatable part pickup locations for the robot.

-

Implement a cleaning program to remove chips from the work area before part placement in the vise, preventing misalignment and setup errors.