WheelyMate

Wheelchair Storage Solution Device

US National Runner up winner of the James Dyson International Competition

Background

The objective of this project is to conceptualize, design, and develop a viable product that could address a gap in the market. Our team chose to design a wheelchair storage solution device, a product that aims to improve the convenience and accessibility of wheelchair users. This project is part one of a two-course sequence (ME691 & ME692), focusing on the upfront efforts of Product Design, from Market Requirements Documents (MRD) and Product Requirements Documents (PRD) to product specifications, initial concept generation, down-selection, and final detailing.

"The storage solution we designed aimed to provide wheelchair users with a simple, efficient way to store and transport their personal belongings, ultimately empowering them to achieve greater independence in their daily lives."

Product Summary

WheelyMate is a versatile device designed to hold multiple accessories, which can be attached, slid, or hung for easy access and convenience.

The main device consists of two components: a bar and redesigned armrests

The accessories include:

-

Bag Clips: For securely attaching bags to the device.

-

Clip-on Tray: A collapsible tray perfect for holding personal items or meals while on the go.

-

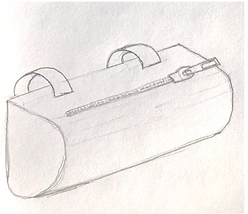

Fanny Pack: A compact storage solution for carrying essentials.

-

Bags: Including a waterproof large bag with zipper and two smaller collapsible bags.

-

Off the shelf accessories

Technical Details

Through extensive market research and direct conversations with wheelchair users, we came to understand just how complex the challenge really was. That insight shaped the entire design approach; the product was built with simplicity at its core.

The rationale? Avoid adding any extra complexity to the daily routines of wheelchair users.

How? Design a solution that looks integrated and can be added easily to the original wheelchair.

Where? Strong user preference was given to placing the device within the user’s reach.

The solution? A redesigned armrest with an integrated tube, allowing a bar to slide in and lock securely at any position. With a strong base, the design supports multiple accessories to accommodate anything the user wants to carry.

Sounds simple, right? Keep reading to see how it all comes together.

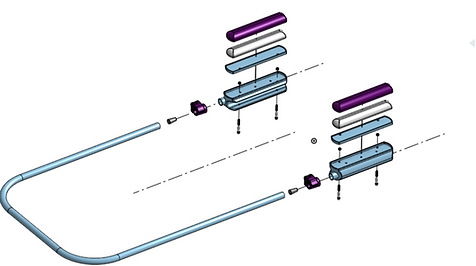

The armrest consists of the key components below:

1: Armrest Base

-

Material: Aluminum 6061 for high strength-to-weight ratio, and excellent machinability.

-

Prototype: Sand casted and machined to create precise slots for the cushion insert and to drill the necessary holes for assembly

-

Production: Extruded and CNC drilled

2: Threaded inserts, supplier-sourced

3: Cushion Insert

-

Material: plastic

-

Prototype: 3D printed

-

Production: Injection molded

4: Cushion Leather, supplier-sourced, custom-shaped for final integration

5: Armrest foam, supplier-sourced, custom-shaped for final integration

6: Screws, supplier-sourced

The bar

-

Material: 5052 aluminum

-

Prototype: bending

-

Production: Extruded and bent; final material to be selected following further analysis. Considering a collapsible bar for compact storage and transport.

-

Weight limit: It can hold up to 70 lbs with a safety factor of 3.

-

The bar can slide in and out of the armrest and be positioned anywhere the user prefers, then securely locked in place using G-locks.

Full Assembly

It’s important to note that most manual wheelchairs have a standardized armrest placement, with the armrests typically screwed into the wheelchair at consistent positions, maintaining the same distance apart based on the wheelchair’s size. This uniformity ensures that WheelyMate can be easily adapted to a wide range of wheelchairs.

Initial mockups and process development

Manufacturing Processes Summary

Accessories

Tray: Easily clips onto the bar and can hold a laptop, lunchbox, notebook, cup holder, and more.

It can easily be moved to the side when not in use.

The bottom picture illustrates how Side A can slide into Side B, with a 5-inch support in the center.

Clips: Easily clipped onto the bar and can hold bags, backpacks, and more.

Soft fabric is attached at the sliding interface to allow smooth movement and ease of use around corners.

Grocery bags: Securely attach to the bar clips using a shortened strap, offering a safe and convenient space to carry groceries or other personal items.

Fanny bag: Attaches to the side of the bar with a Velcro strip, providing a convenient space to store everyday items like a phone, keys, medications, and more.

Video Demonstration

Click the video below to see a demonstration of how the device works. This video serves as a proof of concept for the product.

Outcomes/lesson learned

-

Successfully developed a new product by progressing through initial concept development, down selection, and final detailing, including creating CAD models, BOMs, and fully dimensioned production drawings and assembly instructions.

-

Gathered customer requirements through surveys, interviews, market research, and analysis of user needs.

-

Created mockups for prototype testing.

-

Implemented various manufacturing processes such as sand casting, bending, molding, sewing, thermoforming, 3D printing, and basic hand tools.

-

Troubleshot and resolved design challenges based on customer feedback and engineering specifications.

-

Led the team in project planning, documentation, and emphasized the importance of identifying and addressing high-risk issues early in the process.

Future recommendations

-

Modular Design: Divide the bar into multiple segments to simplify packaging and user assembly.

-

Lightweight Armrests: Further reduce armrest weight to enhance comfort and portability.

-

Customization Options: Introduce color and finish variations to match different wheelchair aesthetics.

-

Accessory Expansion: Develop additional accessory types to increase functionality and user personalization.

-

Enhanced Clip Security: Add a locking mechanism to the clips for improved stability during use.

-

Measurement Markings: Print scale markings directly on the bar for consistent and easy positioning.

-

Mechanical Optimization: Perform advanced simulations to maximize the weight capacity without compromising safety.