Rotary Vane Pump

Background

The goal of this project is to gain hands-on experience in how manufacturing processes affect design decisions and how this chain of design decisions affects the production cost.

Technical Details

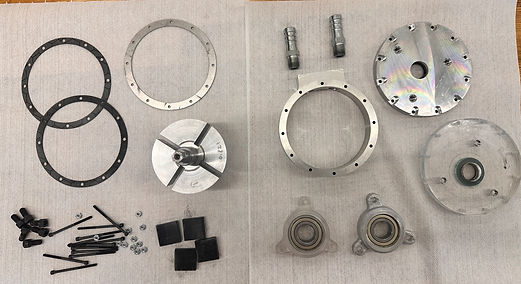

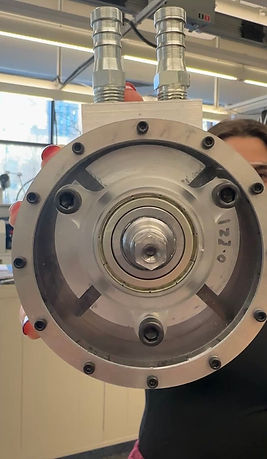

Part 1: Build the pump

-

Learned the fundamental manufacturing processes of: Milling, Turning, Cutting with Water Jet and Laser Cutters, Sheet Metal techniques, Welding, and Sand Casting, among others.

-

Machined the pump's parts based on engineering drawings and engineering specifications.

Click on the link below to watch the video that showcases the entire process of manufacturing the pump from stock materials using various manufacturing processes.

Part 2: Redesign the pump

-

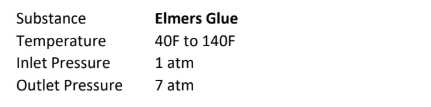

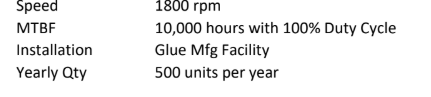

Applied engineering design concepts to redesign the rotary vane pump for Elmer's glue application based on the specifications below:

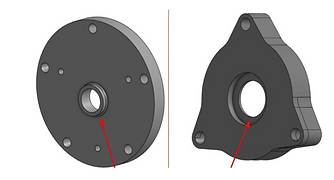

3D CAD of the redesigned pump

Design Modifications

Production cost

Below is the BOM and production cost for one pump, calculated using a software called aPriori. This tool enabled us to select variables that impact manufacturing decisions, such as material costs, manufacturing location, shipping, production processes, and more.

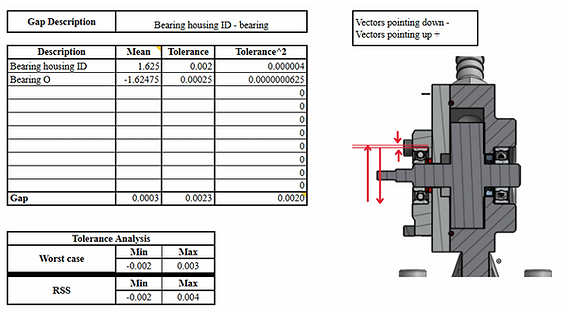

Tolerance Analysis

Housing-Rotor

0.023

Ball Bearing-Bearing Housing

Housing ID-Rotor Thickness

Ball Bearing-Shaft

Outcomes/lesson learned

Before

After

-

TOTAL parts count: 53

-

Manufacturing Cost: $350

-

Assembly time: 10 mins

-

TOTAL parts count: 35

-

Manufacturing Cost: $241.66

-

Assembly time: 4 mins

-

Gained expertise in material selection for pump applications utilizing Granta EduPack software.

-

Developed an understanding of design decisions based on the manufacturing processes involved in pump production.

-

Conducted geometric dimensioning and tolerancing (GD&T) for the pump's 2D technical drawings.

-

Applied Design for Manufacturing and Assembly (DFMA) principles to optimize the pump design for Elmer's glue.

-

Utilized aPriori software to predict production costs by uploading CAD files and selecting appropriate manufacturing processes.

-

Performed tolerance analysis for key components of the pump to ensure precision and quality.