Automated Loading and Imaging of Microtiter plates

*Rendered Image of the Designed Machine*

Background

This project involves designing an automated system to transfer microtiter plates from multiple racks into an imaging device, which will then capture images of the wells on each plate.

Product Requirement

Technical Details

The slideshow below will demonstrate the process of the machine with description under each image.

Feel free to move to the next image by clicking on the arrow. You can also double click on the image to see them in the large mode.

The racks that are powered by a DC brush motor start moving towards the arm

The first rack stops when a laser beam sensor with reflectors align with the beginning and end of the rack

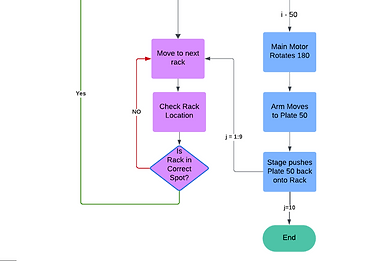

The same process repeats until 50 plates on 10 racks are complete

The racks that are powered by a DC brush motor start moving towards the arm

Description of the components of the middle section of the machine

Note that the components shown in the pictures above are a non detailed representation of this section of the machine. They represent a proof of concept

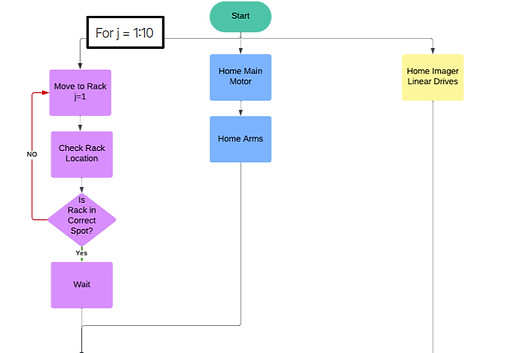

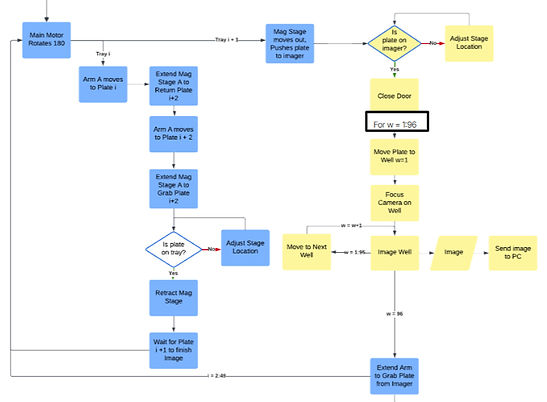

Controls Flowchart

User Interface Screen

Outcomes/lesson learned

-

Used Pugh chart to identify critical risk factors in each concept generate within the group

-

Developed a complete 3D CAD model including all actuators, motors, drives, key sensors, and structure, but no fasteners (holes, screws, etc)

-

Calculated motor size and provided a list of all the actuators, motors, drives, and key sensors including manufacturer and model number.

-

Provided a representative User Interface Screen

-

Provided a flow chart representing control software

-

Performed financial justification