WEBS

Wheelchair Elevator Button System

Background

WEBS is an innovative accessory designed to augment power wheelchairs, specifically catering to individuals affected by Muscular Dystrophy. This technology facilitates enhanced mobility and accessibility for users by extending their reach beyond the confines of their wheelchair's footprint

Technical Details

Product Design Process:

-

Initiated the design process with a weighted benefit analysis to evaluate concept feasibility and prioritize requirements.

-

Applied DFMA principles by using bar stock and off-the-shelf components to create a simple, low-cost, manufacturable mechanism.

-

Produced fully detailed 2D engineering drawings in SolidWorks for fabrication and review.

-

Leveraged the wheelchair’s existing motion to streamline the mechanism, reducing overall complexity, size, and cost.

-

Built the first functional prototype to validate the core concept and guide the next stage of product development.

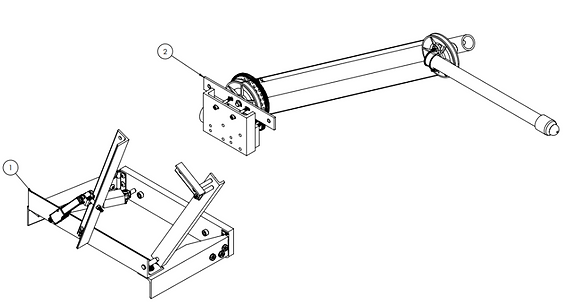

The device is composed of two main mechanisms. The first one is the deployment mechanism that will release the device out of its tucked position so it doesn’t interfere with the armrest when deployed. Next, is the button pusher mechanism that will perform the task of pushing elevator buttons at different levels.

Click Below for the user's manual

Design Improvements

Double click on box to expand

We changed the geometry of the end effector to a silicon ball. The spherical shape will solve the problem related to hitting buttons at an angle and reduce the impact to protect the elevator buttons

Controls and Deployment Process

Outcomes/lesson learned

-

Successfully designed and built a working prototype that met customer requirements and engineering specifications.

-

Developed physical mockups to evaluate form, reach envelope, and user interaction.

-

Executed core manufacturing processes, including lathe turning, milling, vertical press operations, tapping, laser cutting, and precision drilling and assembled components using standard hand tools.

-

Diagnosed and resolved design issues through iterative testing and root-cause analysis, improving reliability and usability.

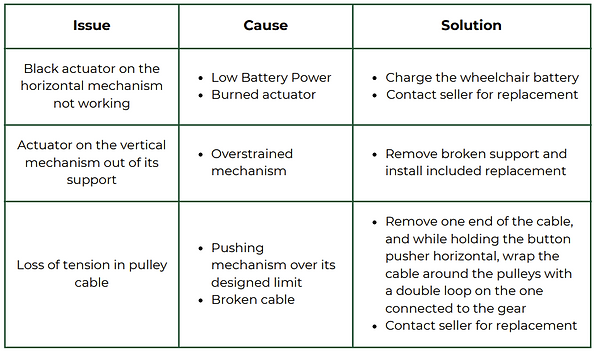

Below is a summary table outlining key problems encountered and the engineering solutions explored.

Future recommendation

-

Increase system robustness: Improve structural durability by selecting higher-strength materials, reinforcing joints, and validating performance under repeated loading conditions.

-

Evaluate alternative materials: consider lighter or higher-strength materials to reduce operating force and improve overall durability.

-

Introduce more adjustability and flexibility: Incorporate adaptive linkages or telescoping components to support a wider range of user reach profiles and wheelchair configurations.

-

Expand testing coverage: Conduct more extensive fatigue, cycle-testing, and user validation sessions to reduce deployment time and ensure consistent real-world performance.

-

Refine ergonomics and usability: Enhance grips, interfaces, and mounting methods to make setup easier and reduce user effort.